|

| photo source: the manual.com Honest work can result in dirty hands, no embarrassment here. |

If the name fits, own it. I do. This is not about the glory work. It's about the tedious dirty, messy work.

|

| The Doctor will see you! |

There are some very dirty jobs that have to be done to complete a project. It's hard to keep the garage clean during these operations. It's also hard to keep my hands clean. I always make it a point to wear gloves, as I don't enjoy having greasy dirt under my fingernails or staining my hands and fingers. I also have plenty of water less hand cleaner available.

I don't consider grease stained hands as a badge of honor.

|

| A very simple but useful tool. |

I had previously made a special tool to allow me to use a hand held grease gun to force the seized wheel cylinder pistons out. It was just a bolt that fit into the hydraulic hose port, and was drilled to hold a grease fitting. A couple of other bolts were used to block off the output fluid port. I was using a newly purchased grease gun from Harbor Freight. It can generate 4,500 lbs. of pressure.

|

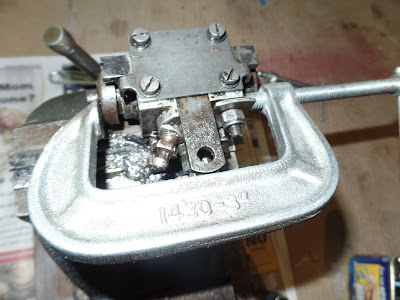

| A vise comes in handy. |

There was a problem when I hooked up the grease gun to the rear wheel cylinders. These have two opposing pistons, when I initially applied pressure only one of the pistons broke free and began moving. That was what I wanted but how was I going to break the opposing piston free if the other one popped out? The answer was to restrain the loosened piston with a pretty cobbled up looking set up. I used two clamps to restrain one piston at a time. It looks kind of goofy but it turned out to be quite effective. I'll come up with something better next time.

|

| I actually used two clamps but one fell off before I could snap the picture. |

That square plate covers the handbrake actuator mechanism. There's a cam and roller set up inside that expands the side arms when the central cable connection is pulled on. It's a system unlike anything that I've ever seen. I had previously disassembled the handbrake actuator and done a preliminary clean up. Now I cleaned up the components on my shop grinder's wire wheel.

|

| Now it's the brake master cylinder's turn. |

Feeling pretty jazzed at this point, I dove into the master cylinders. I decided to work on the brake master cylinder first. I removed the lock ring that also held the push rod to the assembly and shot some Kroil onto the piston cup. Then I screwed my grease fitting plug into the intake port and found a bolt that would sort of fit into the output port. After a few pumps I watched as the piston began creeping into view. That was really easy. Cleaning out all that grease won't be.

|

| The clutch master goes next. |

The clutch master cylinder was just as easy.

|

| I was impressed by how easy it was. |

The slave cylinder was the easiest of all. There wasn't even a lock ring to remove.

Now I was really on a roll.

I still had the left front wheel cylinders to do. I hadn't gotten around to them in the first round. They yielded quickly to the power of the grease gun.

|

| It had been so frustrating trying to use a hydraulic press. |

After disassembly the biggest job is to clean out all the grease. It takes a few rounds to remove the bulk of the grease and progressively clean it with degreaser and finally with brake cleaner. There can't be any traces of grease left or it will contaminate the brake fluid and possibly cause the brake seals and piston seals to soften and swell.

After I disassembled the rear brake cylinders I was about to reach for my drill powered hone when I realized that these were made of aluminum. I couldn't run a three stone hone through them without causing more damage than benefit. So I decided to use a ball of fine steel wool which I pushed back and forth through the bore using various devices lubricated by Kroil.

Even if the bores are a little out of round I think that the rubber piston seals should be able to compensate for that condition, for awhile, at least. Instead of lasting for 40 thousand miles they might wear and start to leak in 10-15 thousand miles. Who knows? As long as they last for awhile. How many miles would I be likely to put on this car anyway?

|

| Probably the best restoration magazine out there. |

Back when I was a subscriber to the restoration magazine, "Skinned Knuckles" there was a featured contributor Bob Harmon, from out in rural Colorado. He documented the "restorations" of various cars over the years. I use quotation marks because his methods were not like the currently favored method of complete disassembly followed by complete replacement, refurbishment and renewal. He would just fix what the car needed. If he found that the car had a leak in the radiator, he would fix the leak, if possible. If that wouldn't work, he would replace the radiator, hopefully with a good used one. He would generally put a new brake seal kit in, he'd replace linings and hoses if it was necessary. If not, bolt it up and get it on the road. If a car had been sitting for a long time or if there were rust holes in the oil pan he would pull the pan, clean it out, weld up the holes, and clean the oil pump pick up. Oh, he might wiggle the rods to see if there was a lot of play. If he saw evidence of metal in the sludge he might pull a rod or main cap to see what the bearings looked like. If not, onward and upward!

I am not disparaging the man's methods. He was "fixing up" an old car. Oftentimes the job required bodywork, painting and even reupholstery. But he only did what the car needed. I've recently been asked if I'm going to "restore" this Mark VII. "You know, get it painted, redo the interior" people will ask. That's the term that they know from the TV shows. I always answer that with, "I'm just going to fix it up a bit. We'll see."

I'm just going to do what the car needs, and does it need a lot!

No comments:

Post a Comment