Today I started my hose replacement project on the '07 Mustang. Part One.

|

| These are almost all the components. I didn't realize at this time that I was still missing one heater hose. I also had been given the wrong upper hose. |

Here's a picture of all the hoses.

Here's the serpentine belt kit.

|

| This kit from Rock Auto is the most economical way to secure the parts. It was less than half the cost of the parts from the auto store. |

Now that I've got the parts, I need to prepare the car. I had to determine a time when my Daughter wasn't going to need the car for a couple of days. I didn't think that the project would be too involved but as always, unseen problems and complications can arise. Best to have some wiggle room in the scheduling.

To get started, I've got to jack up the car and place it on ramps and jack stands. This arrangement gives plenty of working room underneath the car.

|

| The ramps usually give me enough room to work underneath. I use a floor jack to raise the car and set it on the ramps, I don't try driving it up. |

|

| Always place jack stands underneath the car as back up. Safety first. |

Then to drain all the coolant. I have an old brass planter that works out great for this task. It has a wide opening and plenty of capacity. I placed in inside an up side down large storage container lid to catch most of the spills. It fits easily under the car.

| Removing the air intake tubing gave me an unobstructed view. |

A few years ago I had a problem with the thermostat housing weeping coolant, the techs at my quickie oil change place never even mentioned it to me. The housing looked like a grey piece of extra crispy chicken! I ended up replacing the top of the housing as well as the thermostat, bypass hose and upper radiator hose.

|

| That by pass hose is only five years old but doesn't generate a lot of confidence. It was actually okay but I think the hose was a bit big for the fitting. The new hose fit much better. |

|

| The white residue is evidence of current seepage. Ford loves using plastic parts and you have to keep an eye on them. |

This time I'm replacing everything, not because its leaking now, but because it will leak sometime in the unknown future.

Upper and lower radiator hoses, bypass hose, all four heater hoses, thermostat and housing, and coolant tank cap.

I'm also replacing the serpentine belt and tensioner assembly.

|

| You can also take a picture with your phone to keep track of how it goes back together. |

The adoption of the serpentine belt was a great advancement in engine design. The downside was the loss of the ability to remove a dedicated belt from a component, from the a/c compressor as an example, should that unit malfunction and seize up. The benefit was to ensure proper tension on the drive belt via the automatic tensioner. Not to mention a reduction in clutter. Combine that with a modern cars radiator mounted electric fan, and the deletion of the separate distributor, and it's much easier to work on these motors. The life span of these belts far exceeds those separate fan belts of the past.

There used to be a diagram illustrating the belt routing pasted under the hood. I looked, but couldn't find one here. Another 2 cents saved by Ford. I dew up my own diagram.

Things proceeded smoothly I didn't spill much coolant. As I was laying out the replacement hoses I realized that I was short one heater hose. I had sourced three of them through my local Napa supply and had ordered the last one from the Ford dealer.

Things had been pretty hectic around the house, I thought that I had ordered the hose, but had I misplaced all my receipts and I wasn't sure. I called the dealer and asked the parts guy if there was a hose that was supposed to be picked up by me, the parts guy didn't sound very helpful, but then I could even provide the date of the transaction, let alone the invoice number. I told them that I would call back with more info. I asked my Wife if she had noticed a charge to the dealer and she had noticed a thirty something dollar charge the day that I bought the remote key cover for the Flex. The date was June 16th. It turns out that I paid cash for the cover and charged the hose. I called back and this time, a women answered my call. I supplied her with the date of the transaction, she was much more helpful and told me that the hose had arrived, but that they had been unable to contact me. I had provided my burner phone number, which I often have turned off.

It was available almost a month ago, but a lot keeps happening around here, and it had slipped my mind. A quick trip to the dealer and I had my hose. I stopped at the auto parts store on the way home to pick up my thermostat housing, some hose clamps and some coolant. Did you know that the concentrated coolant sells for 30.00 dollars a gallon? I needed three, and the bill was going to be close to a hundred dollars. Holy Cow! I told the parts counterman that I would do another NAPA bucket 20% deal, like I did when I ordered the thermostat housing the day before. He agreed to give me a discount without my buying another bucket. I ended up paying only 17.00 a gallon. It pays to do business with a local store!

I decided to re-use the original spring type clamps on my connections but those on the bypass hose were best fitted with worm clamps. I used to wonder why GM used the wire type spring clamps on their OEM installations, I noticed that when I used to work there, many years ago. Once I brought it up to Dad who also worked there.

He told me they were used for production efficiency. They were, a one and done deal. If they were in the proper location they were always the right tension, it was engineered in. The next time I was at the body drop area I noted the special locking pliers that held the clamps and how quickly they could be installed. It made sense, the worm type clamp, though of stainless steel, took quite a bit of time to tighten and you weren't always certain that they were properly tightened. It was one thing to go back and tighten a clamp on a home repair, quite another to tighten them on 45 units an hour production. line.

I'm only mentioning this because I was introduced to Ford's ( new to me) push on heater hose connectors. Of course these were used on the firewall connections where space is very tight. These two hoses connect to a manifold of metal tubing that is bolted to the right side of the motor. This connects to the hoses on the right side of the engine itself. It would be quick to snap the main hoses on before the engine was installed then merely connect them to the manifold which is already installed on the motor.

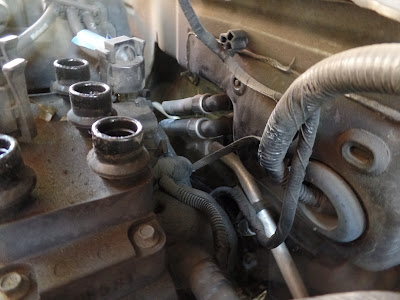

|

| There they are, hidden in a recess behind the motor. I learned that restricted access to the hoses is now a Ford thing. |

I ended up watching several Youtube videos which helped me understand how they worked. Hopefully I'll be able to remove then tomorrow. It looks like I'll have to remove the coil pack to gain more access. The guy in the video referred to it as the distributor, but the motor doesn't use one. That should be simple, I had already removed a breather hose, and a wire conduit that passed along the back of the intake manifold

It is usually easier to work on the smaller engine variant of a car. The motor isn't as long and there's usually more room to work. The Mustang is not too bad, actually the later V6 motors have proven to make a very practical Mustang.

I was going to at least button up the front of the motor after installing the belt, but I discovered that I'd been given the wrong upper hose, oh well, another trip to the store.

This seems like a good time to take a break.

No comments:

Post a Comment