I said that there was never anything easy with a Jag,

|

| photo source: memebase-cheezburger.com Quit yer bellyaching! |

I was right.

I just received the new 2021 registration sticker and was anxious to attach it, so I could start driving the car again.

I pulled the plate frame so I could properly position the sticker, then I decided that I would use the car to run some errands. It was fine at first. About a half mile from home the tranny started to feel kind of funny, like it didn't want to engage properly. I drove some more and a transmission warning light came on. Maybe I better head back. I turned it around and headed back home. The trans felt worse and worse, and why did I smell transmission fluid? I pulled over as the car would hardly move. I'd never had trans problems before.

I opened the hood and the top of the engine was covered with fluid. I figured that one of the return hoses was leaking. I checked the dip stick and it was dry. It was a serious leak, oil was forcefully squirting out of the damaged ribber line. If the car was a patient he would have bled out!

I wasn't too far from home, I figured that if I could add enough fluid I could drive it home. I called my Wife who was able to come pick me up. She drove me to the auto parts store where I picked up four quarts of fluid, then stopped by the house to pick up my transmission funnel. When I returned to the car I poured in three qts. I closed the hood, fired it up, and put it into gear. It engaged and I took off towards home. The transmission warning light went out and the transmission seemed to shift normally. I was a couple of blocks out when the warning light came back on. I kept going until I had the car safely in my driveway.

I was glad to have the car in my driveway but it dripped a lot of fluid leaving a huge mess. I started throwing kitty litter under the car.

I added another quart then backed up the car to try to clean up the mess. I put some cardboard under to catch the drips. It's going to take a lot of cleaning.

Back in the day, my old 60's American cars had just used a length of low pressure oil line to bridge the hard metal line from the transmission to the fittings on the radiator. It was cheap and easy to replace. My Jag has a cooler line that looks a lot like a brake hose, a rubber hose joined with a crimped metal fitting to the metal pipe. The rubber potion is about two feet long, then transitions in the same manner to hard lines that run under the engine.

I started to search the forum for suggestions. A few guys had just cut the line and spliced a rubber hose onto the metal hard line, and that's what I planned to do. From what I understand, these lines are no longer available.

I spent a long time in a funk, I thought that just finding the part was going to be hard. I've been having an equally difficult time sourcing the heater hoses for my '07 Mustang, I was surprised that even the dealer did not carry those hoses in stock. I was just moping around too disgusted to even take any closer looks at the Jag.

What am I going to do when my other older vehicles need hose replacements? The hoses are also quite expensive. Admittedly, these newer hoses last a long time, ten years is not unusual. What would I do?

I'd improvise! I can use straight sections joining bent metal sections. I can bend up some metal tubes myself and use sections of hose at the ends. I could fabricate a water manifold to route coolant hoses. I could fab up a prototype in wood than take it to a welder to actually make the item.

I did an intensive internet search looking for metal hose connectors. There are various angles, curves, and multiple hose connections. Summit products offers several radiator hose kits that incorporate sections of straight and curving rubber hose along with a couple of metal connectors.

I found all this research to be empowering, it gave me the impetus to get off my butt and get to work. No more moping, no more whining, no more crying, no more self pity, just get to work! Adapt, improvise and overcome!

|

| Using a tubing cutter seemed like an elegant solution. But it didn't work, the metal collar would start to spin. |

My plan is to cut the crimped fitting with a tubing cutter, then I can retain the barbed portion of the hard line and attach the rubber splice. It should work out fine, I'm going to replace both of the existing rubber hose portions. I was amazed at how much fluid was lost in so short a time frame. It wasn't just a steady weep or drip, it was an arterial spurt. The car had to be stopped within a mile or so. It would have been a devastating failure if it had occurred on the road.

I had suffered a similar failure with my '71 Riviera, I had been given the wrong type of hose when I replaced it. I had used fuel line, which had quickly deteriorated and started to leak. I had cut the end off and topped up fluid which had allowed me to drive the car home. It was leaking pretty bad and it was the smell of the fluid that alerted me, but it wasn't like the torrent shooting out of the Jag.

The tubing cutter didn't work out, it started the cut, then the collar on the hose started spinning. So I just cut off the end of the hose and secured it in a vise. I used a hacksaw to cut through the collar. I easily removed the remnant of the hose. The upper end of the hoses was the easy part.

|

| These hose cutters cut the old hose and trimmed the new lengths. |

|

| It's easy to work on things if you can remove them from the car. |

To gain some space to work, I removed the air box and MAS. It looks like I'll be cleaning it prior to re-installation.

|

| The MAS sits right next to the coolant tank. |

|

| A two foot long set of pliers can sure come in handy! |

The cooler lines are not separate hoses from the pipes that run under the engine to the transmission. I had thought that there might be threaded fittings that I could undo, and work with the hose ends in the vice. So I had to remove the remnants of the hose from the metal pipes in situ. I did one at a time. First I cut the rubber hose off. I tried to cut all the hose from the coupling and then tried to pull it off with a long pair of pliers. I figured that if I could pull the rubber out, I could pry the collar off. It didn't work. I couldn't get my hacksaw in the space. If I had a cutting tool, maybe I could run down to the hardware store...

Then I remembered, my Wife has a Dremel tool, with different bits.

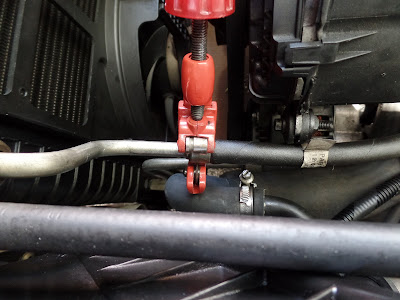

I borrowed the tool fitted with a cut off wheel and made short work of the metal collars.

Now the metal fittings were exposed and clean. Now off to the auto parts store to buy some low pressure oil hose.

I had read some entries on a thread about transmission cooler line replacement. They all did what I did, but a couple stated that they used fuel line. Fuel line looks the same but it cannot handle even the low pressure of this application, and the rubber will degrade from the oil and the hose will fail. I had that happen years ago when I used the wrong hose.

I bought a six foot length of transmission cooler/ low pressure power steering hose, I like to have plenty of surplus to allow for routing. I learned that when I rewired my Uncle's '49 Cadillac. When I made up the harnesses for my '70 Mustang I left them plenty long to find the best routing and then trimmed them to fit. It makes a much more satisfying job. Sure you can extend wire by soldering in extensions but it just looks and feels tacky. Better to leave it long and end up with leftover scrap sections.

|

| Plenty of extra hose. |

After I had connected up the hoses I placed a section of split water hose over an area where one of the transmission lines might rub against a hose clamp. I wanted this fix to last for a long while. Then I reassembled the MAS and air box.

I added five qts. of ATF, then fired up the motor and backed the car into the street. I let it idle for 15 minutes while I cleaned up the driveway with kitty litter. From watching tow operators I learned the trick of grinding a second application of litter into the pavement after the initial application soaked up the fluid. It leaves the concrete looking lighter and cleaner.

|

| This was a solid oil slick before I hit it with the litter. |

A twenty mile test drive revealed no leakage, and fortunately the transmission seems to function as normal. I was very satisfied with my results.

Best of all I traded action for inertia, and just fixed the thing. No more excuses. It certainly wasn't going to fix itself! I really like this car and I hope to move forward with the suspension work soon.

|

| This is why your Wife doesn't want you working on your car in the driveway. |

No comments:

Post a Comment